Why aluminium for PV mounting and solar racking

Aluminium has the ideal properties for use in photovoltaic systems:

- Click‑and‑plug connections speed assembly and reduce tools on site.

- High strength‑to‑weight ratio simplifies handling and transport.

- Natural corrosion resistance and durable finishes for long service life.

- Consistent tolerances enable fast alignment and fewer adjustments.

Faster installation with click‑and‑plug connections

Aluminium extruded profiles enable click-and-plug connections and require fewer individual parts and components, simplifying both assembly and disassembly. The result is fewer work steps, reduced labor, and greater overall efficiency.

Strength, stiffness, and corrosion resistance

Aluminium’s excellent corrosion resistance and strength-to-weight ratio make it ideal for solar racking systems. Commonly used 6xxx-series alloys provide the right balance of formability, mechanical performance, and long-term durability, ensuring stable installations even in harsh outdoor environments.

Surface finishes

The outstanding properties of aluminium can be enhanced by various finishing or surface treatments, such as anodizing or powder coating, providing enhanced UV and salt-spray resistance for long-term outdoor performance.

Why Hydro for Solar Mounting Profiles

Sustainability and Circularity

Hydro offers aluminium solutions that combine performance, durability, and a clear commitment to sustainability. Through advanced recycling, low-carbon production, and global expertise in extrusion, we help solar system manufacturers reduce environmental impact across the entire value chain.

Why Hydro:

- Design and engineering support from experienced extrusion specialists.

- Low-carbon and recycled aluminium options to help reduce the carbon footprint.

- Global extrusion and finishing footprint ensuring reliable, local supply. Anodized and powder-coated finishes for long-lasting performance in harsh environments.

- Take-back and recycling pathways supporting true circularity.

Low-Carbon and Recycled Aluminium Supply

Hydro provides aluminium profiles with verified recycled content and transparent environmental footprint documentation. Customers can select from a range of low-carbon and post-consumer recycled aluminium options that support sustainability targets and compliance requirements.

Certifications and Compliance

Hydro’s production sites operate under internationally recognized standards for quality, environment, and energy management (such as ISO 9001, ISO 14001, and ISO 50001). Environmental Product Declarations (EPDs) and product footprint statements are available upon request.

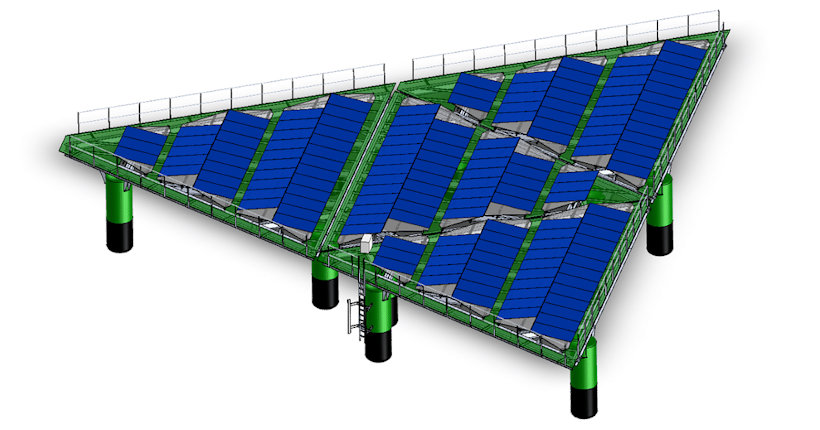

Applications

- Solar rails and PV racking profiles

- Module frames and edge trims

- Clamps, brackets, and fastener interfaces

- Cable trays and wire management channels

- Inverter and power electronics heat sinks

- Tracker components and ground‑mount structures

Watch the video where engineer Florian Schnetzer explains some of the advantages of using aluminium in solar applications.

Updated: October 16, 2025